Andrew Schutte, General Manager,COUNTERPART

Andrew Schutte, General Manager,COUNTERPARTReducing complexity with engineer-to-order (ETO) automation is finally possible

More than 50% of all manufacturers now acknowledge aspects of plant operations include customization. Many ETO companies assume it is impossible to automate the entire end-to-end process surrounding product configuration, design, engineering, and production.

The history and projections of ETO

Fifteen years ago (2005), approximately 25% of all North American manufacturers were ETO (Engineer-to-Order), yet very few knew it. They referred to themselves as custom manufacturers or manufacturers within a particular sector.

The greatest growth trajectory in the ETO space since 2005

Given the projected growth trajectory of engineer-to-order manufacturing over the next five years, rapid deployment of focused ERP technology solutions, like COUNTERPART will ensure the high profit margins which make manufacturers gravitate toward customization and meet the unique demands of customers.

Complex manufacturers must determine ETO status

ETO manufacturers build unique products designed to customer specifications and each product requires a unique set of item numbers, bills of material (BOMs), and routings. Estimates and quotations are required to win business; as technology gains from efficient software systems ranging from ERP (enterprise resource planning) to knowledge-based engineering, business operations have improved for ETO manufacturers as well as profit margins.

Products are complex with long lead times, typically months or even years, material is purchased for a specific project not for inventory. All actual costs are allocated to a project and tracked against the original estimate.

Automation honors the engineering-centric ETO manufacturer

Until recently few ETO technology solutions were truly best-in-class.

Technology which improves the manufacturing process by honoring the engineering teams has been distinctly absent for those managing ETO projects. Engineer-to-order manufacturers have many active projects with long lead times, require project-management capabilities to plan and schedule the stages of a project and communicate to customers.

COUNTERPART automation technology empowers engineers with the knowledge whether a project is on-schedule and on-budget. Automation provides real-time visibility of potential problems or overruns which must be corrected before costs escalate. Only when project management and the ability to collect and report costs are automated, can the potential profitability be realized.

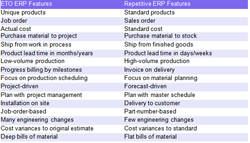

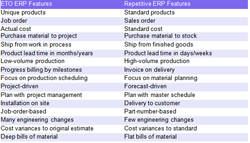

ETO and Repetitive ERP Compared

ETO and Repetitive ERP Compared

Enter SOLIDWORKS® integration

Without integration to SOLIDWORKS engineers must manually enter data into property fields (causing potential human error). Alternatively, non-engineering administrators may manually enter data into fields inaccurately as well.

These fields can be directly automated into an ETO ERP technology, but sadly are often placed into a spreadsheet. It makes no sense with an automated technology model that someone is manually reentering data. These mistakes cause incorrect parts to be produced, costing both time and money.

Authenticated SOLIDWORKS integration eliminates the need for dual entry of properties. By setting material, finish, description, and other qualities in SOLIDWORKS, everyone in the organization can see the information.

According to Andrew Schutte, General Manager of COUNTERPART, when running an engineer-to-order company it is critical to meet client expectations consistently. Schutte shared, “At the same time, you must take on as large a workload as possible to maintain throughput and revenue. This all starts with the engineers who must effectively manage job timelines; an expedient handoff and streamlining reliable dates to engineering, procurement, manufacturing, and assembly is a must have. This can only happen with bi-directional SOLIDWORKS integration, eliminating all double entry without importing and exporting of BOMs. The result is saving valuable time and improving accuracy while effectively communicating partial or full BOMs to purchasing and manufacturing.”

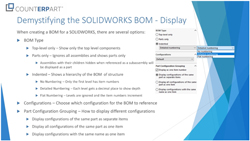

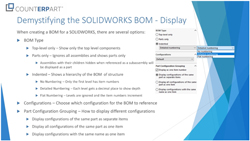

Fully indented BOM without creating a drawing drives enterprise-wide visibility

Most engineers will finalize a design, then create drawings. This can cause some confusion as the SOLIDWORKS feature tree does not group like parts together. Frequently, the engineering team needs to create a drawing to view the BOM. With this leading technology integration, as soon as engineers create an assembly, the BOM is dynamically updated without having to create the drawing. Engineers can simply create the BOM which is automatically synchronized to the ETO ERP solution.

ETO manufacturers must automate frequent BOM changes

ETO manufacturers must automate frequent BOM changes

With older technologies, when an engineer designed a dimensionally perfect component it frequently required material changes creating a significant production problem. With the new best-in-class ETO ERP solution, changing the material in SOLIDWORKS is accomplished with ease; engineers no longer need to create a revision.

Stop creating false BOMs

Engineering-centric manufacturers have created workarounds to cope with the older ETO ERP solutions. Workarounds included creating false BOMs, then cancelling individual items, then reordering them later as part of the BOM, hoping that procurement remembers to order.

Automating this process eliminates double orders and ensures engineer-to-order manufacturers optimize operations and profitability.

COUNTERPART automation technology empowers engineers with the knowledge whether a project is on-schedule and on-budget. Automation provides real-time visibility of potential problems or overruns which must be corrected before costs escalate. Only when project management and the ability to collect and report costs are automated, can the potential profitability be realized.

ETO and Repetitive ERP Compared

ETO and Repetitive ERP ComparedEnter SOLIDWORKS® integration

Without integration to SOLIDWORKS engineers must manually enter data into property fields (causing potential human error). Alternatively, non-engineering administrators may manually enter data into fields inaccurately as well.

These fields can be directly automated into an ETO ERP technology, but sadly are often placed into a spreadsheet. It makes no sense with an automated technology model that someone is manually reentering data. These mistakes cause incorrect parts to be produced, costing both time and money.

Authenticated SOLIDWORKS integration eliminates the need for dual entry of properties. By setting material, finish, description, and other qualities in SOLIDWORKS, everyone in the organization can see the information.

According to Andrew Schutte, General Manager of COUNTERPART, when running an engineer-to-order company it is critical to meet client expectations consistently. Schutte shared, “At the same time, you must take on as large a workload as possible to maintain throughput and revenue. This all starts with the engineers who must effectively manage job timelines; an expedient handoff and streamlining reliable dates to engineering, procurement, manufacturing, and assembly is a must have. This can only happen with bi-directional SOLIDWORKS integration, eliminating all double entry without importing and exporting of BOMs. The result is saving valuable time and improving accuracy while effectively communicating partial or full BOMs to purchasing and manufacturing.”

Fully indented BOM without creating a drawing drives enterprise-wide visibility

Most engineers will finalize a design, then create drawings. This can cause some confusion as the SOLIDWORKS feature tree does not group like parts together. Frequently, the engineering team needs to create a drawing to view the BOM. With this leading technology integration, as soon as engineers create an assembly, the BOM is dynamically updated without having to create the drawing. Engineers can simply create the BOM which is automatically synchronized to the ETO ERP solution.

ETO manufacturers must automate frequent BOM changes

ETO manufacturers must automate frequent BOM changes With older technologies, when an engineer designed a dimensionally perfect component it frequently required material changes creating a significant production problem. With the new best-in-class ETO ERP solution, changing the material in SOLIDWORKS is accomplished with ease; engineers no longer need to create a revision.

Stop creating false BOMs

Engineering-centric manufacturers have created workarounds to cope with the older ETO ERP solutions. Workarounds included creating false BOMs, then cancelling individual items, then reordering them later as part of the BOM, hoping that procurement remembers to order.

Automating this process eliminates double orders and ensures engineer-to-order manufacturers optimize operations and profitability.

|

Share this Article:

Tweet

|

Top